Container cranes are essential pieces of equipment for ports, logistics hubs, and container terminals. They are designed to efficiently handle, stack, and transfer shipping containers between vessels, trucks, and storage yards. Investing in a high-quality container crane for sale is crucial for optimizing container handling operations, improving productivity, and ensuring safety. However, with so many options available, finding the right container crane can be a daunting task. This guide provides valuable tips to help you navigate the process and find the top container crane for sale that meets your operational needs.

Assess Your Operational Requirements

Before beginning your search for a container crane for sale, it is essential to thoroughly assess your specific needs. Different container handling operations may require cranes with varying capacities, reach, and features. Key factors to consider include:

a. Crane Capacity

The lifting capacity of the crane is one of the most important specifications to evaluate. Ensure that the crane can handle the weight of the containers you are dealing with. Most container cranes are designed to lift loads ranging from 40 tons to over 100 tons, depending on the model and manufacturer. Be sure to choose a crane that matches the weight of the containers you need to handle, considering any future increases in cargo volume.

b. Reach and Height

The reach of the crane is crucial, especially for container terminals handling large vessels. Ensure that the crane can reach over the length of the ship and place containers at the required height. Some container cranes are designed with adjustable booms or rails to increase their reach, allowing them to service a wider range of vessels.

c. Operational Environment

Consider the environment in which the crane will operate. For example, outdoor operations in harsh weather conditions, such as high winds or saltwater environments, will require cranes made from durable, corrosion-resistant materials. Similarly, if your site has limited space, consider cranes that are designed for tight spaces or have a smaller footprint.

d. Speed and Efficiency

Efficiency is key in container handling operations. Look for cranes with fast cycle times, high speed hoisting, and fast trolley movements to maximize productivity. The crane should also offer smooth and precise controls to reduce downtime and increase operational efficiency.

Research Different Types of Container Cranes

Container cranes come in various types, each with distinct features suited for specific applications. Understanding the types available will help you narrow down your search and select the best option for your needs.

a. Ship-to-Shore (STS) Cranes

Ship-to-shore cranes, also known as quay cranes, are used to load and unload containers from ships. These cranes are designed with long booms that can reach across large vessels. STS cranes are typically high-capacity machines capable of handling very large containers, making them ideal for ports with deep-water docks and large container vessels.

b. Rubber-Tyred Gantry Cranes (RTG)

Rubber-tyred gantry cranes are used for stacking containers in yard areas, offering mobility across different locations within the terminal. They are versatile and highly efficient, capable of lifting containers from ground level and stacking them in various configurations. RTGs are particularly suitable for busy container terminals that require flexible operations.

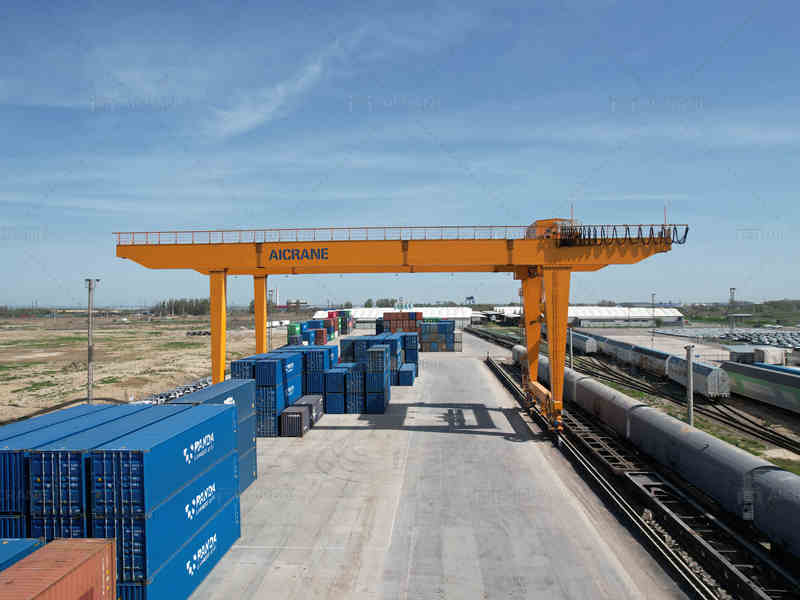

c. Rail-Mounted Gantry Cranes (RMG)

Rail-mounted gantry cranes are similar to RTGs but are mounted on rails, providing greater stability and higher lifting capacities. These cranes (https://aicranemachine.com/gantry-crane/rail-mounted/) are typically used in container yards and intermodal facilities to handle container stacks efficiently and with precision.

d. Straddle Carriers

Straddle carriers are another type of container crane used to transport and stack containers in terminals. These cranes offer greater flexibility, with the ability to operate in tight spaces and maneuver around other equipment in the terminal.

Each type of crane has its specific use case, so be sure to evaluate your terminal’s needs to determine which type will deliver the best results.

Evaluate Crane Manufacturers and Suppliers

When looking for a container crane for sale, the manufacturer’s reputation and experience in the industry are vital. Established manufacturers like Aicrane are more likely to produce reliable, durable, and well-engineered cranes that can withstand heavy usage in demanding environments.

a. Reputation and Reviews

Research the manufacturer’s reputation within the industry. Look for customer reviews, testimonials, and case studies that highlight their reliability and quality. Suppliers with positive feedback and a strong track record are likely to provide you with high-quality cranes and excellent customer service.

b. After-Sales Support

A reliable after-sales service package is essential to ensure that your crane remains operational and efficient over time. Check for warranties, maintenance packages, and parts availability. A top manufacturer will provide comprehensive support, including spare parts, training for operators, and remote diagnostic capabilities to troubleshoot issues quickly.

Consider the Total Cost of Ownership

The container crane for sale price is not the only factor you should consider. The total cost of ownership (TCO) includes several factors that affect the long-term cost of operating and maintaining the crane.

a. Initial Price

While the initial price is an important consideration, opting for the cheapest option may not always be the best choice. A more expensive crane might offer better efficiency, longer lifespan, and lower maintenance costs, ultimately providing better value in the long run.

b. Maintenance and Spare Parts

Cranes require regular maintenance to operate at peak performance. Check the availability of spare parts and the cost of ongoing maintenance. Ensure that the crane comes with easy access to replacement parts and that the manufacturer provides clear maintenance instructions.

c. Energy Efficiency

Some cranes come with energy-saving features such as regenerative braking systems, which can help reduce electricity consumption over time. A more energy-efficient crane will lower operational costs and reduce your environmental footprint.

Inspect the Crane’s Build Quality

The construction and quality of materials used in the crane are crucial for its longevity and ability to perform under challenging conditions. Ensure that the crane is made with durable, high-quality materials that can withstand harsh environments. Key areas to focus on include:

a. Frame and Structure

The frame should be made from robust materials, such as high-grade steel, to ensure that the crane can handle heavy lifting loads and harsh weather conditions.

b. Corrosion Resistance

For cranes operating near coastal or saltwater areas, corrosion resistance is essential. Look for cranes with anti-corrosion coatings or stainless steel components that can endure exposure to harsh conditions.

c. Safety Features

Safety features should be a priority when selecting a crane. Look for cranes with overload protection, anti-sway systems, emergency stop buttons, and warning signals to ensure the safety of operators and equipment.

Test the Crane Before Purchase

Whenever possible, request to test the crane before purchasing it. This will allow you to assess its operational performance and ensure that it meets your requirements. Pay attention to the ease of use, lifting speed, precision, and the overall smoothness of operation.

Negotiate the Purchase

When you have selected a container crane for sale, don’t be afraid to negotiate the price. You may be able to secure a better deal by discussing discounts, financing options, or bundling the crane with additional services, such as installation or operator training.

Purchasing a container crane for sale is a significant investment that requires careful consideration of several factors, including your operational needs, the crane’s specifications, the manufacturer’s reputation, and the total cost of ownership. By researching and evaluating different options, you can find the right crane that maximizes your efficiency and productivity in container handling operations. A top-quality crane will enhance your operational performance, ensure safe and reliable container handling, and provide value for your business for many years.